Share to

Polyanionic cellulose with high viscosity

Still deciding? Get samples first, Contact US !

View similar products

- Product description

-

The PAC produced by our company has high technological content and stable performance. As a project to fill the scientific and technological gap in Hebei Province, it has been awarded the honor of "Hebei Province Science and Technology Progress First Prize" by the Provincial Department of Science and Technology. Polyanionic cellulose (PAC) belongs to the ionic cellulose ether class and is an advanced replacement product of carboxymethyl cellulose (CMC). It is a white, off white or slightly yellow powder or particle, non-toxic, odorless, easily soluble in water, forming a transparent solution with a certain viscosity, with good heat stability and salt resistance, and strong antibacterial properties. It has the characteristics of high purity, high degree of substitution, and uniform distribution of substituents. Can be used as a binder, thickener, rheology regulator, fluid loss agent, etc. Polyanionic cellulose has a wide range of applications and can be used in all industries where carboxymethyl cellulose (CMC) can be used, providing more stable application performance. For example: 1. It can be used as a lightweight yarn sizing agent to replace starch in the textile industry; 2. Adding pulp to papermaking can improve the longitudinal strength and smoothness of the paper, as well as enhance its oil resistance and ink absorption; 3. Used in the daily chemical industry to prepare soap and synthetic detergents; 4. Used as a latex stabilizer in the rubber industry; 5. In addition, in the fine chemical processing of coatings, food, cosmetics, ceramic powder, leather, etc., it is used as a thickening agent, lotion stabilizer, crystallization prevention agent, thickening agent, adhesive, suspending agent, water retaining agent, dispersant, etc. The mud fluid formulated with this product has good water loss reduction, inhibition, high temperature resistance, and salt resistance. Widely used in oil drilling, especially suitable for deep wells, high-temperature wells, saltwater wells, and offshore oil drilling.

1. Suitable for any mud ranging from freshwater to saturated saltwater. PAC has excellent solubility characteristics and can form transparent liquids with certain viscosity and shear force in freshwater, saltwater, or saturated saltwater. It also has good colloidal properties, especially in saltwater, which can resist flocculation and maintain its original colloidal structure as much as possible. This is essential for forming high-quality mud cakes, which ordinary CMC cannot achieve.

2. High slurry production rate, PAC's slurry production can reach 2-3 times that of ordinary CMC. A large number of application experiments have shown that under the same application environment, the dosage of PAC is significantly less than that of CMC; In saltwater or saturated saltwater, the amount of PAC used for slurry production is significantly higher than that of CMC;

PAC is the best filtrate reducer, with strong filtrate reducing ability not only in freshwater mud, but also in seawater or saturated saltwater. Low viscosity PAC can effectively reduce filtration loss without significantly increasing system mucus, especially in high solid content systems; High viscosity PAC has a high slurry production capacity and significant filtration and water loss reduction effect, especially suitable for low solid phase mud and solid free saline mud. It can achieve better suspension, filtration and wall building effects than CMC, as well as better wellbore control capabilities.

The mud fluid prepared by PAC can suppress the dispersion and expansion of clay and shale in high salt media, thereby controlling wellbore pollution. Due to the full unfolding of molecular chains and increased adsorption capacity, PAC is better able to fully encapsulate drill cuttings and clay than CMC; In addition, PAC has a stronger ability to reduce filtration loss, so it has a greater ability to inhibit clay hydration expansion. Whether through bubble tests or viscosity tests, it has been proven that PAC can greatly delay the hydration, expansion, and dispersion time of clay.

4. Good protective colloid ability. The use of a large amount of diluent to enhance the dispersibility of the slurry may increase the solid content during its circulation process. The advantage of this mud is good fluidity, with low dynamic and static shear forces; The disadvantage is: (1) The mud cake is soft and thick, which can easily cause pressure difference and drill jamming. (2). Once the solid content is high, it is easily contaminated by salt and gypsum, resulting in a significant increase in dynamic and static shear forces, mainly due to the poor colloid properties of this type of mud. When PAC is used in this type of mud, the diluent has little effect on the PAC colloid, so even if it is contaminated by salt paste under high solid phase, the shear force fluctuation of the mud can be greatly reduced. In addition, the mud prepared with PAC does not require too much clay even when suspending heavy spar.

Compared with CMC, PAC can be used in many complex formations such as salt, gypsum layers, high temperatures, as well as difficult drilling conditions such as oceans and deserts, to achieve better technical and economic benefits. As oil development enters a period of oil scarcity, shallow oil is no longer sufficient to meet demand. Oil producing countries are actively exploring and developing deep and offshore oil, resulting in a significant increase in formation temperature and salt paste content. Ordinary CMC products in this field cannot meet technical needs. PAC products with excellent performance have an irreplaceable position. The temperature of deep wells and ocean drilling formations is mostly above 145 ℃, and the salt paste content is above 30ppb. Ordinary CMC generally has temperature and salt resistance up to saturated saltwater concentration, while KC1 concentration can only reach 15ppb, while PAC products can reach above 35ppb; Ordinary CMC products have poor stability. When the temperature exceeds 80 ℃, the molecular chains break and rapidly decompose, almost completely failing, resulting in increased water loss, reduced dynamic shear force, and easy wellbore shrinkage, wellbore collapse, and reduced chip carrying capacity, which cannot meet the process requirements. However, PAC products can still maintain high application performance at high temperatures above 150 ℃.

6. Excellent mud drilling and workover fluids are also efficient fracturing fluids. Application of PAC: 1. Application of PAC in drilling fluid. PAC is ideal for use as an inhibitor and fluid loss agent. The mud fluid formulated with PAC can suppress the dispersion and expansion of clay and shale in high salt media, thereby controlling wellbore pollution. 2. The application of PAC in well repair fluids. The well repair fluid prepared with PAC is low solid phase, which will not block the permeability of the production layer due to solids and will not damage the production layer; And it has a low water loss, which reduces the amount of water entering the production layer, and the incoming water will form a water stagnation phenomenon due to emulsion blockage. The well repair fluid formulated with PAC provides advantages that other well repair fluids do not have: A. Protect the production layer from permanent damage; B. Capable of carrying clean wellbore and reducing maintenance workload; C. Has the ability to resist water and sediment infiltration, and rarely foams; D. Can be stored or reused between wells, with lower cost compared to general mud repair fluids. 3. The application of PAC in fracturing fluid. The fracturing fluid prepared with PAC can withstand 2% KCI solution (which must be added when preparing the fracturing fluid) and has good solubility. It is easy to use, can be prepared on site, and has fast gelation speed and strong sand carrying capacity. When used in low-permeability formations, its fracturing effect is more outstanding.

Storage: CMC should be stored in a cool and dry place with a temperature below 40 ℃ and a relative humidity below 75%

Under the above conditions, it can be stored for 24 months from the date of production;

Packaging: Made of 25kg/bag composite paper

The PAC produced by our company has high technological content and stable performance. As a project to fill the scientific and technological gap in Hebei Province, it has been awarded the honor of "Hebei Province Science and Technology Progress First Prize" by the Provincial Department of Science and Technology. Polyanionic cellulose (PAC) belongs to the ionic cellulose ether class and is an advanced replacement product of carboxymethyl cellulose (CMC). It is a white, off white or slightly yellow powder or particle, non-toxic, odorless, easily soluble in water, forming a transparent solution with a certain viscosity, with good heat stability and salt resistance, and strong antibacterial properties. It has the characteristics of high purity, high degree of substitution, and uniform distribution of substituents. Can be used as a binder, thickener, rheology regulator, fluid loss agent, etc. Polyanionic cellulose has a wide range of applications and can be used in all industries where carboxymethyl cellulose (CMC) can be used, providing more stable application performance. For example: 1. It can be used as a lightweight yarn sizing agent to replace starch in the textile industry; 2. Adding pulp to papermaking can improve the longitudinal strength and smoothness of the paper, as well as enhance its oil resistance and ink absorption; 3. Used in the daily chemical industry to prepare soap and synthetic detergents; 4. Used as a latex stabilizer in the rubber industry; 5. In addition, in the fine chemical processing of coatings, food, cosmetics, ceramic powder, leather, etc., it is used as a thickening agent, lotion stabilizer, crystallization prevention agent, thickening agent, adhesive, suspending agent, water retaining agent, dispersant, etc. The mud fluid formulated with this product has good water loss reduction, inhibition, high temperature resistance, and salt resistance. Widely used in oil drilling, especially suitable for deep wells, high-temperature wells, saltwater wells, and offshore oil drilling.

1. Suitable for any mud ranging from freshwater to saturated saltwater. PAC has excellent solubility characteristics and can form transparent liquids with certain viscosity and shear force in freshwater, saltwater, or saturated saltwater. It also has good colloidal properties, especially in saltwater, which can resist flocculation and maintain its original colloidal structure as much as possible. This is essential for forming high-quality mud cakes, which ordinary CMC cannot achieve.

2. High slurry production rate, PAC's slurry production can reach 2-3 times that of ordinary CMC. A large number of application experiments have shown that under the same application environment, the dosage of PAC is significantly less than that of CMC; In saltwater or saturated saltwater, the amount of PAC used for slurry production is significantly higher than that of CMC;

PAC is the best filtrate reducer, with strong filtrate reducing ability not only in freshwater mud, but also in seawater or saturated saltwater. Low viscosity PAC can effectively reduce filtration loss without significantly increasing system mucus, especially in high solid content systems; High viscosity PAC has a high slurry production capacity and significant filtration and water loss reduction effect, especially suitable for low solid phase mud and solid free saline mud. It can achieve better suspension, filtration and wall building effects than CMC, as well as better wellbore control capabilities.

The mud fluid prepared by PAC can suppress the dispersion and expansion of clay and shale in high salt media, thereby controlling wellbore pollution. Due to the full unfolding of molecular chains and increased adsorption capacity, PAC is better able to fully encapsulate drill cuttings and clay than CMC; In addition, PAC has a stronger ability to reduce filtration loss, so it has a greater ability to inhibit clay hydration expansion. Whether through bubble tests or viscosity tests, it has been proven that PAC can greatly delay the hydration, expansion, and dispersion time of clay.

4. Good protective colloid ability. The use of a large amount of diluent to enhance the dispersibility of the slurry may increase the solid content during its circulation process. The advantage of this mud is good fluidity, with low dynamic and static shear forces; The disadvantage is: (1) The mud cake is soft and thick, which can easily cause pressure difference and drill jamming. (2). Once the solid content is high, it is easily contaminated by salt and gypsum, resulting in a significant increase in dynamic and static shear forces, mainly due to the poor colloid properties of this type of mud. When PAC is used in this type of mud, the diluent has little effect on the PAC colloid, so even if it is contaminated by salt paste under high solid phase, the shear force fluctuation of the mud can be greatly reduced. In addition, the mud prepared with PAC does not require too much clay even when suspending heavy spar.

Compared with CMC, PAC can be used in many complex formations such as salt, gypsum layers, high temperatures, as well as difficult drilling conditions such as oceans and deserts, to achieve better technical and economic benefits. As oil development enters a period of oil scarcity, shallow oil is no longer sufficient to meet demand. Oil producing countries are actively exploring and developing deep and offshore oil, resulting in a significant increase in formation temperature and salt paste content. Ordinary CMC products in this field cannot meet technical needs. PAC products with excellent performance have an irreplaceable position. The temperature of deep wells and ocean drilling formations is mostly above 145 ℃, and the salt paste content is above 30ppb. Ordinary CMC generally has temperature and salt resistance up to saturated saltwater concentration, while KC1 concentration can only reach 15ppb, while PAC products can reach above 35ppb; Ordinary CMC products have poor stability. When the temperature exceeds 80 ℃, the molecular chains break and rapidly decompose, almost completely failing, resulting in increased water loss, reduced dynamic shear force, and easy wellbore shrinkage, wellbore collapse, and reduced chip carrying capacity, which cannot meet the process requirements. However, PAC products can still maintain high application performance at high temperatures above 150 ℃.

6. Excellent mud drilling and workover fluids are also efficient fracturing fluids. Application of PAC: 1. Application of PAC in drilling fluid. PAC is ideal for use as an inhibitor and fluid loss agent. The mud fluid formulated with PAC can suppress the dispersion and expansion of clay and shale in high salt media, thereby controlling wellbore pollution. 2. The application of PAC in well repair fluids. The well repair fluid prepared with PAC is low solid phase, which will not block the permeability of the production layer due to solids and will not damage the production layer; And it has a low water loss, which reduces the amount of water entering the production layer, and the incoming water will form a water stagnation phenomenon due to emulsion blockage. The well repair fluid formulated with PAC provides advantages that other well repair fluids do not have: A. Protect the production layer from permanent damage; B. Capable of carrying clean wellbore and reducing maintenance workload; C. Has the ability to resist water and sediment infiltration, and rarely foams; D. Can be stored or reused between wells, with lower cost compared to general mud repair fluids. 3. The application of PAC in fracturing fluid. The fracturing fluid prepared with PAC can withstand 2% KCI solution (which must be added when preparing the fracturing fluid) and has good solubility. It is easy to use, can be prepared on site, and has fast gelation speed and strong sand carrying capacity. When used in low-permeability formations, its fracturing effect is more outstanding.

Storage: CMC should be stored in a cool and dry place with a temperature below 40 ℃ and a relative humidity below 75%

Under the above conditions, it can be stored for 24 months from the date of production;

Packaging: Made of 25kg/bag composite paper

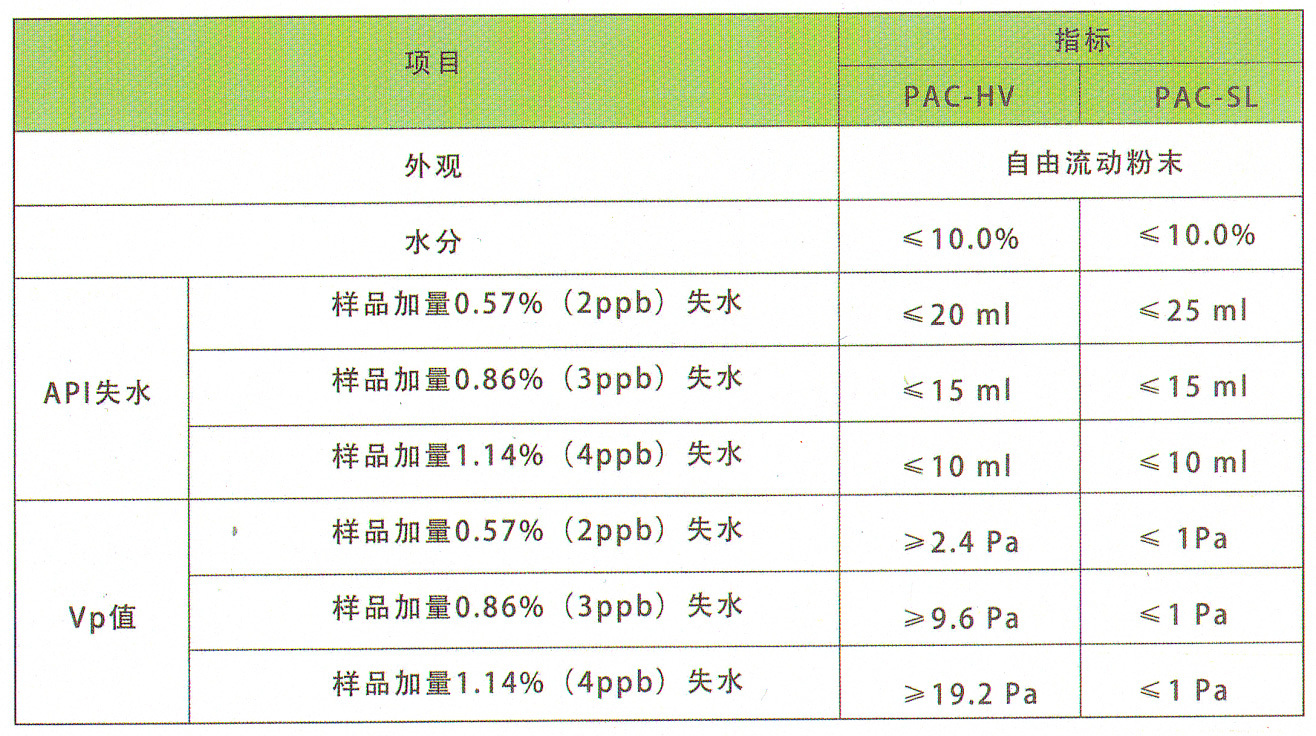

Specifications

Polyanionic cellulose with high viscosity

Still deciding? Get samples first, Contact US !

Products Category

Inquire Now

Note:There is a discount for retaining funds today, Please leave your email address, our professionals will contact you as soon as possible!