Share to

99% purity carboxymethyl cellulose

Still deciding? Get samples first, Contact US !

View similar products

- Product description

-

CMC is a widely used and rapidly developing important water-soluble polymer cellulose ether. The carboxymethyl cellulose sodium produced by our company can be used as emulsifiers, thickeners, sizing agents, film-forming agents, adhesives, etc. Due to its many characteristics that natural and synthetic adhesives do not have, it has been widely used in the tobacco, synthetic washing and soap industry, textile printing and dyeing industry, petroleum drilling mud, paper industry, food industry, coating industry, protective slag, compound fertilizer and other ball forming products, pharmaceuticals, daily chemical industry, construction and civil industries in recent years. Practice has proved that the use of instant CMC not only plays its unique role, but also saves industrial food, making it a rare synthetic rubber product. In order to popularize and promote the application of CMC and facilitate the selection of varieties, this product introduction is specially written for reference.

Chemical name: Sodium carboxymethyl cellulose, also known as carboxymethyl cellulose

Molecular formula: [C6H7O2(OH)2CH2COONa]n

Application in industrial products

1. In the building materials industry, it can be used as a retarder, water retaining agent, thickener, and binder in mechanized construction such as masonry, plastering, and joint filling. After adding instant CMC to the coating, it can thicken and retain water, and have a retarding effect. Even in large-scale construction, it can also improve building strength. Used for plastering gypsum, water-resistant putty, bonding gypsum, and jointing gypsum, it can significantly improve its water retention and bonding strength, and has the characteristics of good workability and no cracking.

2. Used in the ceramic industry as a raw material for adhesives, plasticizers, suspension agents for glazes, fixing agents, etc. Cmc is used as a blank adhesive in the ceramic industry, which can improve the plasticity of clay. Cmc is added to ceramic glazes as a flow control agent, which has the property of retaining the glaze to prevent it from falling off into tear marks before firing and being burned out.

3. Used in the textile and printing and dyeing industries, instant CMC is used as a sizing agent for light yarns of strong fabrics such as cotton, silk, chemical fibers, and blends;

4. Instant CMC can be used as a paper smoothing agent and sizing agent in the papermaking industry. Adding 0.1% to 0.3% instant CMC to pulp can enhance the paper's tensile strength by 40% to 50%, increase its compressive strength by 50%, and increase its workability by 4 to 5 times.

5. Detergent: Instant CMC is used in detergents to prevent the re deposition of dirt, and can also effectively thicken the detergent slurry or soap solution and stabilize the composition structure.

6. Paint: The shelf life of paint is an important characteristic, as it can have a good shelf life without dehydration shrinkage and reduced viscosity. In the application test of instant CMC, it was shown that after heating, the paint did not dehydrate or shrink and could maintain stable viscosity.

7. Used for drilling, digging and other engineering projects related to oil and natural gas

① Mud containing CMC can form a thin and hard filter cake with low permeability in the wellbore, reducing water loss.

② After adding CMC to the mud, the drilling rig can obtain low initial shear force, making it easy for the mud to release the gas trapped inside, and quickly disposing of the debris in the mud pit.

③ Drilling mud, like other suspended dispersions, has a certain existence period, and adding CMC can stabilize it and prolong its existence period.

④ Mud containing CMC is rarely affected by mold, so there is no need to maintain a high pH value or use preservatives.

⑤ Containing CMC as a drilling mud cleaning fluid treatment agent, it can resist pollution from various soluble salts.

⑥ Mud containing CMC has good stability and can reduce water loss even at temperatures above 150 ℃.

CMC with high viscosity and high degree of substitution is suitable for low-density mud, while CMC with low viscosity and high degree of substitution is suitable for high-density mud. The selection of CMC should be determined based on different conditions such as mud type, region, and well depth.

Extend

The high-end alternative to carboxymethyl cellulose (CMC) is polyanionic cellulose (PAC), which is also an anionic cellulose ether with higher degree and uniformity of substitution, shorter molecular chains, and more stable molecular structures. Therefore, it has better salt resistance, acid resistance, calcium resistance, high temperature resistance, and enhanced solubility. Applied to all industries where carboxymethyl cellulose (CMC) can be used, it can provide better stability performance and meet higher process requirements.

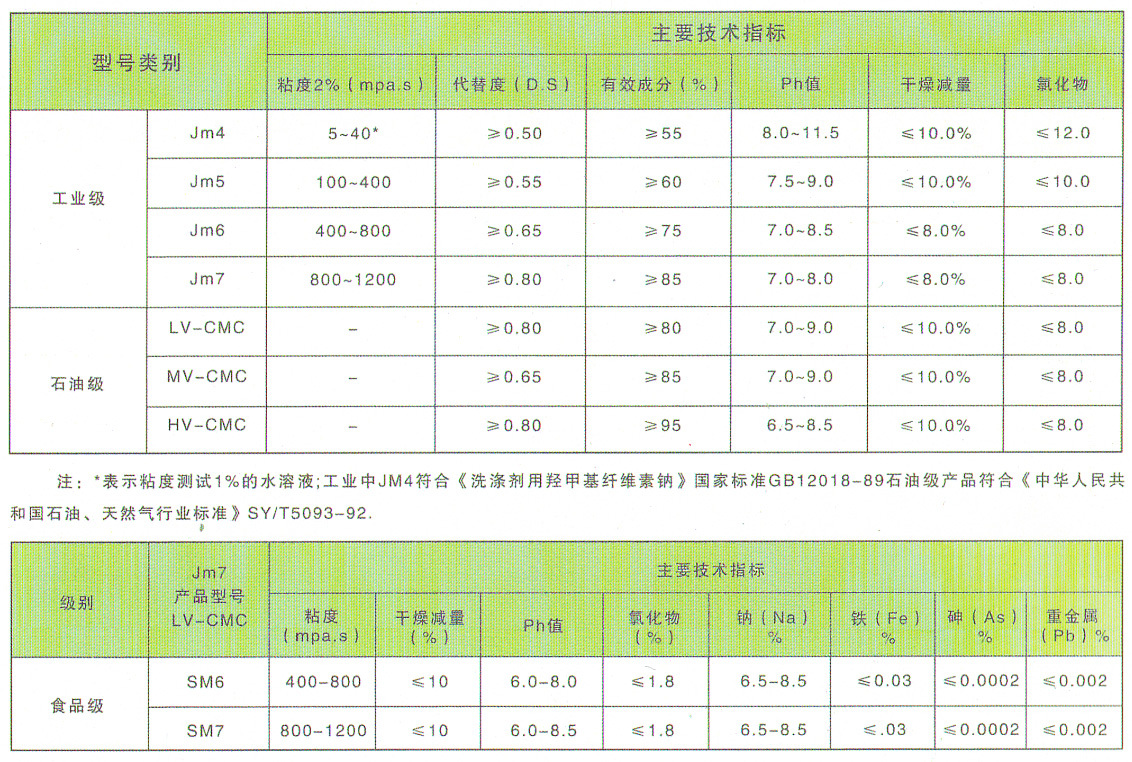

Specifications

99% purity carboxymethyl cellulose

Still deciding? Get samples first, Contact US !

Products Category

Inquire Now

Note:There is a discount for retaining funds today, Please leave your email address, our professionals will contact you as soon as possible!